Engineering the Developing World – IABSE conference

Meinhardt recently presented at the IABSE conference (International Association for Bridge and Structural Engineers) in Kuala Lumpur. The topic of the conference was “Engineering the Developing World”. Dario Feliciangeli, Krzysztof Mierzwa and Mariana Antunes developed a paper which describes the “Fully Stress Laminated Timber Bridge”.

This footbridge extends the timber stress lamination technology, usually applied only to decks, to all its parts. The resulting bridge design combines the easiness of stress ribbon bridges construction with the peculiar robustness of a stress laminated timber deck achieving an exceptional balance between reliability of the structural system, construction cost and sustainability.

The concept designed was developed for the Central Africa region with a chosen span of 30m which would allow the bridge to provide a connection over natural barriers and to be built easily using local timber. Ebiara, the timber species chosen for the structure, includes about twenty species and it naturally grows in West and Central Africa. This material has been used in constructions for many years due to its high mechanical properties and good durability against insect and beetles.

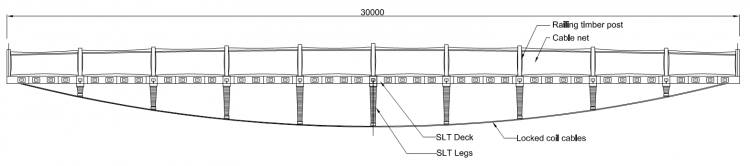

The footbridge is a three-dimensional truss with varying depth, composed by a butt jointed SLT deck, underslung locked coil cables and stress laminated timber legs connecting the cables with the deck (Figure 1)

Figure 1. FLT Footbridge Cross Elevation

Longitudinal joints (i.e. butt joints) are used to span the intended length out of small individual members. Transverse rods are equally spaced along the deck and prestressed to provide the required transverse pressure. SLT legs, varying in length, are rotated thirty degrees in cross section to improve the lateral stability and to give a slender appearance to the footbridge.

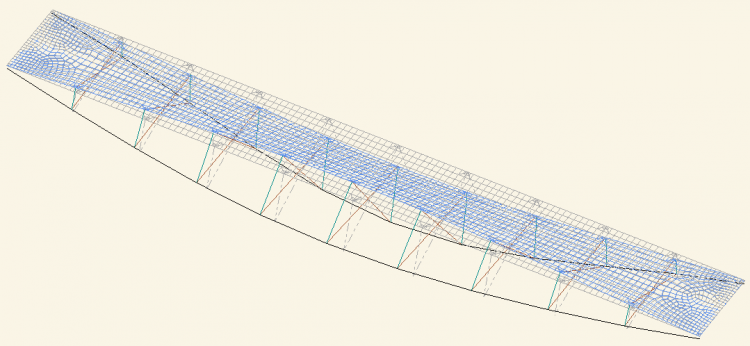

The structure was assessed dynamically (Figure 2) following “SYNPEX” guidelines. The footbridge was designed to have a medium comfort (vertical acceleration between 0,5 m/s2 and 1 m/s2) for a T3 traffic class (0,5 person/m2) and minimum comfort level (vertical acceleration between 1 m/s2 and 2,5 m/s2) for T4 traffic class (1 person/m2). A 3% damping ratio was used.

Figure 2. Modal Analysis

The footbridge is composed by three different types of deck blocks. “SLT Blocks” are composed only by a segment of SLT deck, “Leg Blocks” are the combination of a SLT Block with SLT legs attached to it and “End Blocks” are the extreme blocks carrying cable anchorages. These blocks can be slid on bearing cables following a determined sequence (Figure 3) allowing for an accelerated construction which avoids temporary works and cranes.

Figure 3. Construction Sequence

The conference itself was very successful involving more than 300 delegates from every part of the world being a real platform for international exposure. The paper was presented by Ong Chaow Chiun, director of Meinhardt Kuala Lumpur office, the first day of the conference during a technical session. The presentation was well received by an audience of about 60 delegates who showed their interest in the project asking few questions at the end of the session and after it.